How toilets are made:

Toilets are made from naturally available clay materials. Clay materials are mixed in proper position and then casted to the design needed and sprayed to get the colour and then fired to get the required strength and glossiness.

Do you want to find out how factories around the world manufacture the toilet? Then you come to the right place. In this article we are going to see how toilets are manufactured in sanitary ware industry. We also going to cover the steps in the process, raw materials used and testing done to the toilets. All types of toilets are manufactured in the same method, will not vary based on the design. I am going to write this article like you never know about the toilet manufacturing. So to understand clearly the process, I am going to compare the toilet manufacturing to car manufacturing process to get a clear idea. Toilets are also known as water closets.

Raw materials:

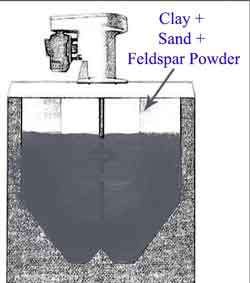

The basic raw materials for the toilet manufacturing are mined from the earth directly. We can classify the raw materials in toilet manufacturing as three parts,

- Raw material for the body.

- Raw material for the Glaze.

- Raw materials for the mould.

The raw material for the body:

First, we see what body is. The body is the one which gives shape and strength to the toilet, Imagine a car without paint. The appearance may not look good but, it the one give the body shape and strength. Without the body, there is nothing in it.

Body is a mixture of following the raw material,

- Ball clay

- China clay.

- Feldspar

- Sand

Ball clay and china clay are added to give the strength of the body before firing the body to 1200 degree Celsius.

Feldspar is added to the body to fuse the body al lower temperature in the kiln. Because the sand melting temperature is 1650 degree Celsius. So to melt it at a lower temperature like 1200 degree Celsius we are adding the feldspar as a flux. Flux materials help us to melt the composition at a lower temperature. We will use both potash and soda feldspar in the mixer to get the desired flux effect.

Sand is the one which gives the strength to the toilet when we are using. A toilet can withstand a minimum of 450 Kgs (Approx. 1000 pounds).

These three main components are mixed with water and made like a watery paste. This is called as the slip.

Raw materials of glaze:

What is a glaze? The glaze is like a paint, it is going to give the colour to the toilet. When you see and colour of toilet including white it is glaze with this glaze. After the firing, Glaze will be shining and gives a good finishing to the body. The glaze will easily mixable in glaze before firing. Don’t think the glaze is like paint. This will never become permanent unless you fire above 1200 degree Celsius. Before firing you can nothing is permanent in the toilet body, it can be easily breakable and also can be recycled completely.

The raw material for the moulds:

What is the mould?. Mould is the one which gives shape to the slip. The mould is made of beta – plaster of Paris. We will see in the process how these moulds are made.

Now we have seen the Materials used in the toilet production. You need to remember the slip, glaze and moulds to understand the process of toilet manufacturing.

Toilet manufacturing process:

We will see the toilet manufacturing step by step. the steps are as follows,

- Designing & Moulding.

- Body and Glaze preparation.

- Casting.

- Drying.

- Spraying.

- Firing.

- Testing.

Designing & Moulding:

In the first step of toilet manufacturing, a design is made for the toilet. Initially, a Cad diagram is made with the size. Below show is a simplified diagram of a toilet diagram. The diagram will help to make a design on plaster. The floor bolt, seat cover whole place, trap way, shape and everything will be included in the diagram.

Once the diagram made a modeller will do a model using the plaster of Paris. The model is made 12% more size than the required toilet size. Because the toilet will shrink during firing. This model-making process will take up to 30 days based on the complexity of the toilet model and the modular experience. Now a day the model can be made using a CNC machine. But still, the machines are not so perfect as manual modelling. Once a model toilet is made using the plaster of Paris, it is used to make a die for the model toilet. This die is called as mould. The mould made up of plaster will have 90 to 100 impression life. We need more moulds to make the toilet production continues. So a die is made for mould, the die may be a rubber, resin or alpha plaster die. This die is known as a case.

Now using the case, many moulds are prepared based on the requirement. How these moulds are prepared from the case?

Water and plaster are mixed with 4:3 ratios using a stirrer. Within five mints the mixer will be poured in the case. Once the plaster mixer hardens the mould will be taken out of the case. The hardening of plaster mould will take up to 20 mints. Then the moulds are taken to the mould drier. The plaster will be dried in the dryer at 65 degree Celsius around 48 hours.

Body and glaze preparation:

First sand is grounded the in ball mill with water to reduce the size of the sand. Then the sand mixer is mixed with ball clay, china clay and fine feldspar powder. Required quality of water is added to the blunger with this mix. The prepared mix is called as Slip. The density, flow and Thixotropic of the slip are maintained to get the required property. The prepared slip will be sent to the Casting process.

The raw materials of the glaze are grinded in the ball mill based on the required colour. Once it is grounded then it is unloaded to send to the spraying process. The glaze will be tested for the property before sent to the next process. The slip will be in grey color and high viscous liquid form.

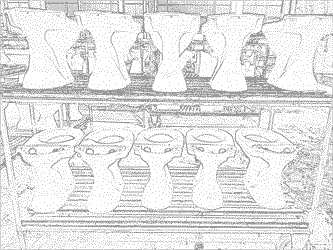

Casting:

The slip will be poured inside the mould and let the slip in the mould for 2 hours to get the shape of the toilet design. The excess slip will be drained form the mould. The thickness of the piece should be around 9 to 13 MM based on the model. After two hours the slip gets dried and can be taken out from the mould. This stage of the toilet is called as green ware. This green ware is allowed to dry for two dasy in open area. Once it si dried then it is finished for any defects.

Drying:

The Green ware is loaded in a trolley and then pushed to the drier. The wares are placed in a 90 degree Celsius drier for 8 to 10 hours. Once the green ware dried the ware is tested for moisture content. The moisture content after drier should be less than 0.5%. These pieces then sent to the spraying area.

Spraying:

The ware piece is sprayed using a spray gun. The glaze from the glaze preparation section is used to spray on the piece. The glaze thickness should be around 1 MM. Then this glazed product sent for firing.

Firing:

The toilets are stacked in a moving car. This car takes the toilets to the firing area. The toilet is fired to a temperature of 1200 degree Celsius. Once the toilet fired it get the strength to withstand weight minimum of 400 degree Celsius.

Testing:

Toilets are tested after firing to guarantee the quality and standards. First visual inspection is done to make sure no defect piece sent to the customer. Then leak test, flush test, vacuum test , smoke test will be done to ensure the toilet quality. This toilet is packed and sent to the consumers.

Conclusion

I tried to include the step in the toilet manufacturing process. If you need anything, let me know on the comment section below. I sure can answer because I work in this manufacturing factory. learn how to start a toilet manufacturing factory.

Could you plz tell me how brand names are printed on these seats

Thank you sir this is so helpful for me

What is the ratio in making the wares.